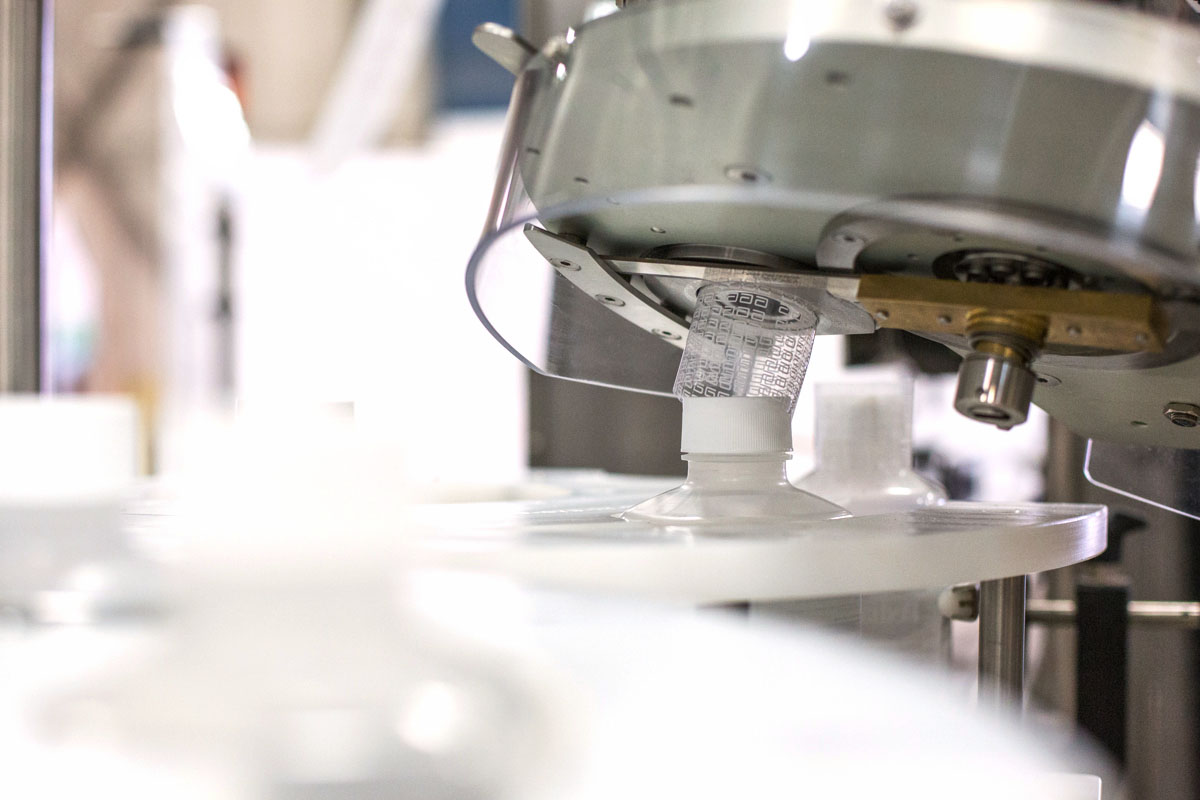

Sleever for Tamper Evident Bands

Our sleever system for tamper evident bands has been carefully designed to improve sleeve quality and efficiency while reducing changeover and maintenance costs. Installed onto an existing labeler, the reduced plant footprint keeps your operation streamlined.

This high speed sleeving system allows precision sleeve application at an economical cost. Used primarily in the food and beverage industry, it has been engineered to withstand the rigors of 24/7 production schedules with minimal maintenance.

Our standard sleever package includes the sleeving head, head supports with auto-height adjustment, reel unwind station, and heat tunnel. The system includes vertical perforation and cut-to-length sleeving, but options are available to allow cut to registration and horizontal perforation.

Features

Our sleever hardware and software has been carefully designed to give you more control than ever over your sleeve application. Cut speed and timing can be adjusted simply and intuitively to ensure perfect sleeve control as it’s cut and placed onto the bottle. Additional optional features like speed based length compensation can be used to ensure your sleeve is perfectly consistent at all your production speeds.

Every element of the sleeving system has been designed to allow rapid and tool free changeover:

- The mandrel can be easily removed to accommodate changes in sleeve size.

- The sleever mounting has been modified to reduce head movement between packages.

- Automated head height adjustment with digital feedback provides quick and reliable changeover.

- Pneumatic feed roller pressure setup allows for quick release of the mandrel and fewer change parts.

Pneumatic assisted feed rollers eliminate the need for secondary pressure devices reducing the change part requirements while allowing for highly controllable sleeve feeding.

With fewer moving parts and a simplified drive system maintenance costs are significantly reduced. The sleever has also been designed to allow each section to be removed and rebuilt separately for easier maintenance without removing the sleeving head from the machine. These features combine to create a sleeving head that reduces downtime and helps keep your plant running.

Our sleever makes the setup process as simple as possible with a setup procedure that’s clear and intuitive. Knife timing is fully recipe controlled resulting in minimal adjustment during package changeover. Mechanical features like geared angle adjustment help to ensure adjustment during setup and changeover is easy and repeatable.

Our sleever has been carefully designed with a minimized footprint to allow it to easily be added to almost any labeler with as few modifications as possible. This reduced footprint also helps to ensure your operators and changeover teams have unrestricted access to your labeler for maintenance and changeover.